My company for various industries, especially the electronics industry supporting various types of precision automatic lathe processing parts. My company for various industries, especially the electronics industry supporting various types of precision automatic lathe processing parts.In addition to automatic lathes, there are auxiliary table lathes, drilling machines, milling machines (slotting machines), tapping machines, rolling machines, etc. Can complete more processes of automatic lathe processing parts. Left is a typical turning part for automatic lathes: embedded nuts for injection molding |

Various screws, non-standard stainless steel screws, stainless steel special thread turning parts, etc. Various screws, non-standard stainless steel screws, stainless steel special thread turning parts, etc.Our company can also customize. For example, multi-step screws, cold pier molding machine can not be extruded products. Or high dimensional accuracy products, and complex shapes of threaded parts and so on. Material limited to: stainless steel / copper / fast cutting steel / aluminum Non-standard turning parts. The left is stainless steel turning parts, click on the left to see more stainless steel turning parts |

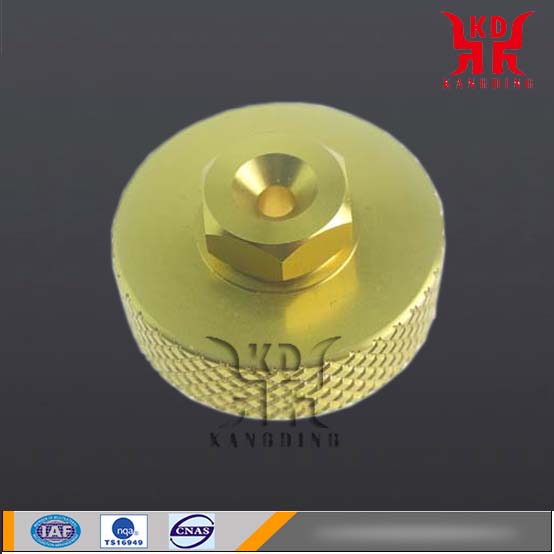

In general, the inner hole tolerance can reach 0.02MM (0.03% for stainless steel or quick-cut steel products), In general, the inner hole tolerance can reach 0.02MM (0.03% for stainless steel or quick-cut steel products),At the same time, the flat bottom hole can be hooked through a hook knife. As well as drilling stepped holes (except eccentric holes) through the forming drill, the roughness of the inner hole can be up to 0.8. According to customer drawings can develop all kinds of parts, turning pieces of non-standard hardware. Left is a copper turning part, see more copper turning parts |

Tiny pins. Used for electronic signal connectors and connector pins. Tiny pins. Used for electronic signal connectors and connector pins.In general, the cylindrical shaft surface tolerance can reach 0.01MM (if it is copper can be 0.005MM), the surface roughness can reach 0.8. Cylindrical centerless grinding, tolerance reached 0.001MM, surface roughness up to 0.2um. This is a non-standard turning part that can not be reached by the cold heading. Tiny machining parts, non-standard lathe turning parts |

PREV:Automatic Lathe Processing

NEXT:NONE

NEXT:NONE